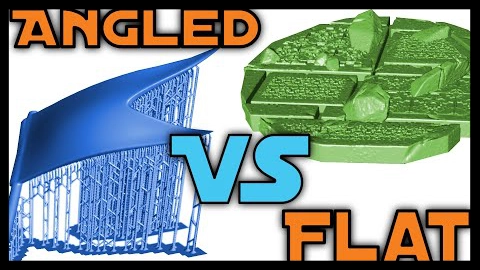

Chitubox Pro – Features Breakdown + Testing

Current Testing Results Country of Origin Shenzhen, China Company CBD-Tech Feature Successfully Tested Open/Save/Export ✅ Select/Move/Rotate/Scale/Mirror ✅ Recently Opened ✅ Merge Export ✅ Section Export ✅ Add Machine ✅ Copy ✅ Split Model ✅ Auto Orientation ✅ Add Tag ✅ …